3.25.2021

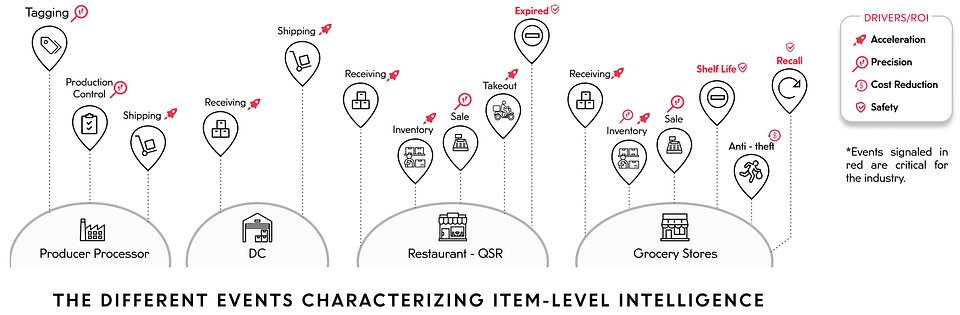

Mojix, a global leader in item-level intelligence solutions for markets that include the restaurant industry, has expanded its SaaS-based solution ytem™ to include specific capabilities for quick serve restaurant (QSR) applications. The solution provides an unprecedented level of visibility into food product lifecycles and supply chains, bringing significant improvements in key areas like customer safety, authentication, waste reduction, operational efficiency, inventory accuracy, and stock optimization.

Food Safety: a growing brand reputation and regulatory concern

The recent publication by the European Commission, A Farm to Fork Strategy, and the Proposed Rule for Food Traceability unveiled by the FDA in late September 2020 reflect a widespread concern on the fronts of both public policy and public opinion. A post-pandemic survey shows that today, “Four out of five people are more likely to patronize a restaurant if they know what steps it is taking to enhance cleanliness, food safety or guest safety and, as a result, would be willing to pay an average of 10% more for the service.” The food industry now has more than one reason to intensify and automate food safety procedures all along the supply chain.

From Supply Chain to Item Chain

With these factors in mind, Mojix developed the item-level intelligence solution for food to meet safety and security challenges by focusing on the following critical areas:

-

Customer Safety – Identification of 100% Recalled and Expired items during Receiving and Inventory operations. Inventory visibility for required track-and-trace in regulatory compliance. The capability to pinpoint specific locations in a recall through unified stock visibility and to trigger actions to remove these products from stock with a completion status.

-

Waste Reduction – Identification of Short Shelf-Life items to enable FEFO (First Expired First Out), or promote items before expiration.

-

Operational Efficiency – RFID Receiving in 5 minutes (75-90% labor savings). Accuracy and speed are also essential for the preservation of foods.

-

Stock Optimization/Omnichannel – 100% Audit of Inbounds and Outbound Shipments – increasingly important with the new trends shaping the restaurant of the future.

-

Authentication and/or Provenance – Counterfeit foods, illegally labeled and grey market goods jeopardize health and safety and cost the industry an estimated $10-15Bn in the US alone.

ytem™ for Food can accurately capture item data in most current formats including RFID, QR code, NFC and BLE Sensor. Once data is captured and stored in the ytem™ platform, it can be processed into a wide range of actionable forms including real-time reporting, business/operational intelligence and predictive analysis. Rules are unlimited and can be pre-defined or auto-generated. Because the Mojix solution is operating in a cloud environment, users can expect high availability and performance combined with a multi-zone, multi-region capability for global real-time data consistency. The solution is highly resilient, scalable and easily integrates via API with EPCIS standards and most ERP, LMS, WMS and WCS systems.

“After successful pilots with a proven ROI, we’re rolling out this year on a large scale with some of the world’s leading QSR players,” said Dan Doles, Mojix President and CEO. “We are proud of the teams at Mojix who were able to execute this continuation of our long-term vision for item chain management by addressing the traceability challenges of our QSR customers. This gives us the confidence to enter new markets that handle perishable goods, such as the cosmetics industry and others.

Does your company have news it would like to share with our readers? If so, we invite you to review our editorial guidelines and submit your press release for publishing consideration.