By Lejjy Gafour, President of CULT Food Science - 4.18.2022

Much of how software and computing have changed how we work day to day, biotechnology and food will do the same for how we eat. The industry goes by many names: cellular agriculture, lab-grown meat, cultured meat, and cultivated meat, to name a few. The technologies of cellular agriculture will shift how we produce food directly and the entire supply chain around it. Something that was once only thought of as science fiction — the ability to create food without needing the animal — is already here today.

You can divide “cellular” and “acellular” approaches. More plainly, it is the production of animal cells and things that use plant cells or microbiological processes to make great products. More in-depth, acellular products are made of organic molecules like proteins and fats and contain no cellular or living material in the final product. One example is milk proteins made with something like yeast. Often it does involve a precision fermentation process. In a general sense, companies are taking something like simple sugar as an input “food” and then using a microbial method to consume the sugar to create their desired product.

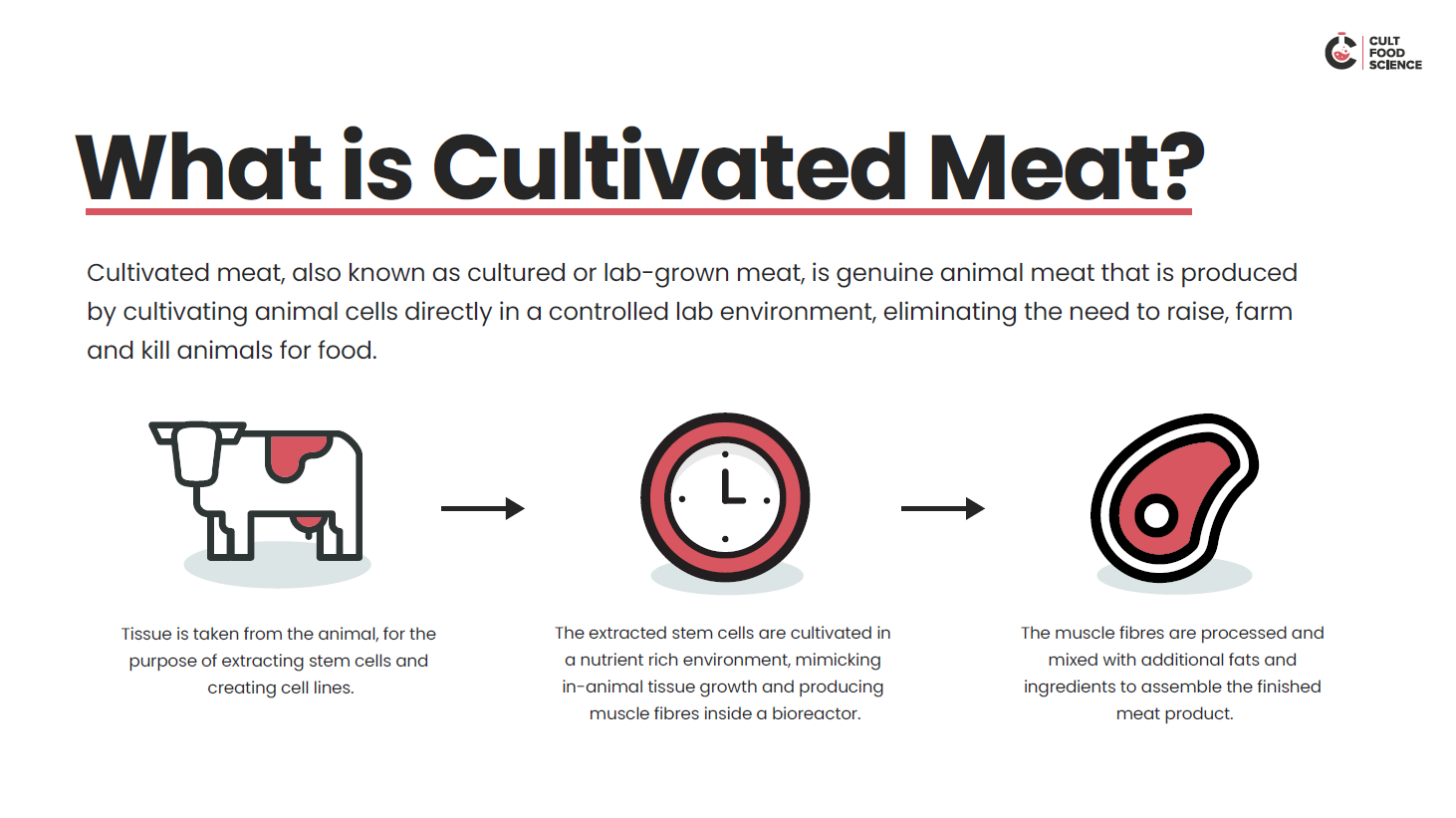

Cellular products are made of living or once-living cells. A company will collect a cell sample at a very high level, grow these cells in a bioreactor with growth media (the “food” cells need to grow), and then harvest the cells to create the final product. The result is the exact products you are used to seeing today made in an entirely novel way.

Cellular products are made of living or once-living cells. A company will collect a cell sample at a very high level, grow these cells in a bioreactor with growth media (the “food” cells need to grow), and then harvest the cells to create the final product. The result is the exact products you are used to seeing today made in an entirely novel way.

The Opportunity in the Restaurant Industry

A more far-reaching implication of cultured meat is the companies working to create culinary experiences and nutrition profiles that are impossible through traditional agriculture. The success of this is evident in Singapore at the restaurant 1880, where cultivated chicken is already being served. The entire experience is more than simply “just” a piece of chicken made in a novel way, which is recognized by customers who have even traveled from outside Singapore to try this new experience. It has expanded beyond the sit-down restaurant experience to include Eat Just’s cell-cultured Good Meat at Loo’s Hainanese Curry Rice in Tiong Bahru, Singapore. All for an affordable price of $4.

Today, companies are working to create meats with enhanced flavors and fat profiles to make novel dishes with unique taste profiles. In Australia, cellular agriculture company VOW is working to develop cultured versions of more exotic meats – such as lion, tortoise, yak, and more. With the common cuts of meat in the western world consisting of beef, chicken, pork, and types of fish, the potential exists to domesticate any animal without needing the animal itself. The range of potential dishes and flavors is unexplored and waiting to be discovered.

Far-Reaching Potential

This idea extends to nearly every product you can think of that typically needs an animal’s body to create. Remember that you are creating these products in a controlled environment rather than an animal, which massively reduces the time, space, water, and potential energy required to make products, enabling production models that are not possible by any other means.

Why ship food from hundreds of miles away into a city when you can build a cellular agriculture “farm” in the middle of downtown to act as your primary supplier? Are you concerned about how the leather for your shoes was produced? Your shoes can be made of genuine leather minus the cow. Supply constraints on a type of fish due to overfishing? That same cut of fish can be produced outside of the ocean. Is an area too arid or too cold to raise livestock? As long as there is the ability to generate enough power to run it, a factory that can produce protein for an area could conceivably be spun up to serve the community.

Your New Supplier Might Be a Cultured Meat Company

With an estimate that the world’s population will be nearly 10 billion by 2050 (9,735,033,900) and with a continuous rise in incomes, people will naturally consume more food — the UN estimates the demand will double by then. But, with the urgent need to cut greenhouse gas emissions and the world’s food systems accounting for over one-third of total global greenhouse gas emissions, we likely do not even have a choice but to create smarter, cleaner, and more sustainable alternatives to feed the world.

Cellular agriculture represents a comprehensive option to reduce the environmental impact of food production, which extends into the potential reduction of food system waste. An estimated 17% of food grown worldwide in 2019 was wasted, amounting to 931 million tons. While the consumer side is often pinned with the blame for wasting food, the supply side is no different. Overproduction and overconsumption leading to waste go hand in hand. At the same time, we risk empty shelves and the ability to handle shocks to our production systems, as we experienced during the pandemic, if we do not have enough slack.

Therein is another potential aim of the cultivated meat industry — the ability to increase or decrease food supply in several months or weeks instead of entire seasons. And allowing restaurant owners and patrons to positively impact the climate by simply choosing to buy products produced through these novel methods.

Lejjy Gafour is the President of CULT Food Science, an innovative platform advancing the future of food with an exclusive focus on cultivated meat, cultured dairy and cell based foods. He is the former co-founder and CEO of Future Fields, a YCombinator backed biotechnology company, and one of the first operating cellular agriculture companies in Canada. He has over 15 years of experience in both public and private enterprises executing strategy, technology, and product development for everything from financial institutions, manufacturing, public health, to world class universities. He is also a founding member of Cellular Agriculture Canada and currently serves on its board.

Lejjy Gafour is the President of CULT Food Science, an innovative platform advancing the future of food with an exclusive focus on cultivated meat, cultured dairy and cell based foods. He is the former co-founder and CEO of Future Fields, a YCombinator backed biotechnology company, and one of the first operating cellular agriculture companies in Canada. He has over 15 years of experience in both public and private enterprises executing strategy, technology, and product development for everything from financial institutions, manufacturing, public health, to world class universities. He is also a founding member of Cellular Agriculture Canada and currently serves on its board.

Are you an industry thought leader with a point of view on restaurant technology that you would like to share with our readers? If so, we invite you to review our editorial guidelines and submit your article for publishing consideration.